Press Release: UNISERS Ships First Fully-Automated Fab Tool

Our technology brings to the market a unique method for molecular particle characterization, enabling customers to find contamination sources faster.

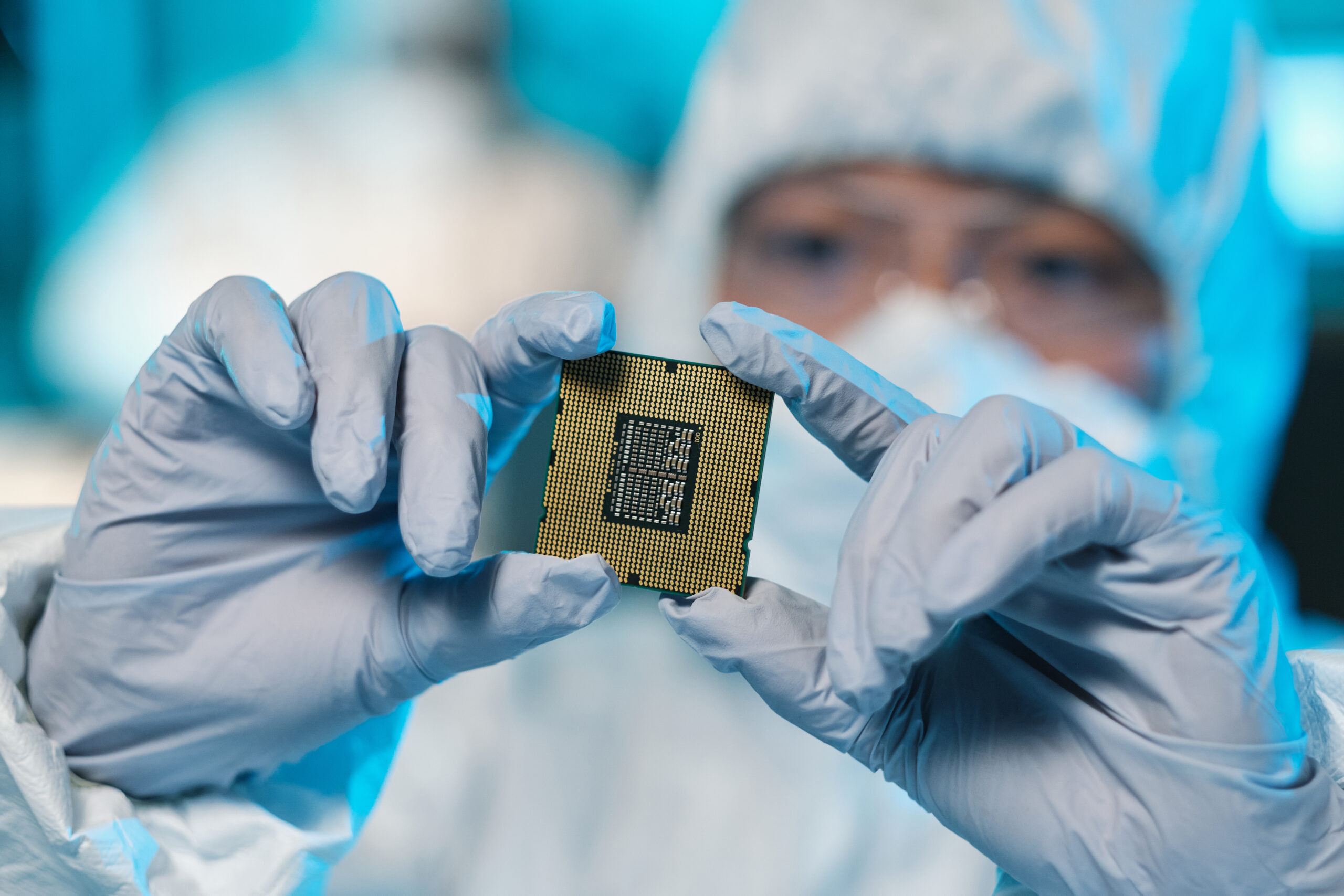

UNISERS’ technology serves the entire semiconductor ecosystem. The areas of applications can be divided into two main categories: Defect Review and Liquid Defectivity.

We have several generations of systems in our laboratories in Zurich to perform automated testing for our customers.

Please reach out to us to discuss how our technology can complement your sample analysis.

Learn more about our revolutionary equipment for defect review and liquid defectivity.